One of the highest quality powder coating technologies is based on acrylic resins. Some of the very first thermosetting powders were based on acrylics, with powder technology based on acrylic resins having been around since the 1970s.

Acrylics provide an array of performance that is truly a cut above the rest, and can offer excellent chemical resistance, superior exterior durability, exceptional chemical resistance and outstanding smoothness. The following is a summary of some acrylic chemistry available in powder coatings and their general performance levels.

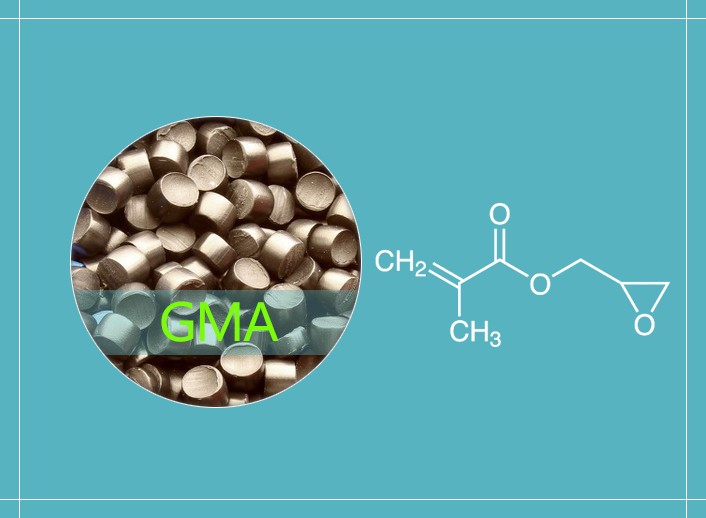

Glycidyl Methacrylate GMA Acrylics

Glycidyl Methacrylate GMA acrylic powders provide excellent smoothness for vehicle application. The acrylic resin supplier PChem© GA-003 (from Pioneer Solutions Americas Inc.) is a Glycidyl Methacrylate GMA acrylic powder that is excellent for high performance of exterior weather-ability, durability and abrasion resistance.

All Glycidyl Methacrylate GMA acrylics are well known for their excellent weathering resistance which can provide coatings resistant to over 10 years of exposure. These types of powder acrylic resin solutions have been used since 1998 as a clear topcoat for BMW automobiles. As you can surmise, not only does this technology possess excellent UV durability, but also remarkable resistance to various environmental conditions, cleaning agents, and even gasoline spills.

Acrylic Polyesters

This may sound a bit strange, but it is actually possible to make a Glycidyl Methacrylate GMA functional acrylic resin react with a carboxyl-polyester (which is a polyester resin formed by reacting one or more aliphatic glycols and one or more polycarboxylic acids and/or anhydrides). Typically this system produces a rather low gloss coating with relatively poor flexibility and impact resistance. This makes acrylic polyesters less desirable than GMA acrylics for vehicle application.

Potential Drawbacks

There are two issues of note with acrylic powder technology. The cost is much higher than other choices for vehicle application, and there can be compatibility issues with other powder coatings as well. Both of these issues can cause manufacturers to reconsider using acrylic powders, in spite of their far superior durability and overall performance.

Compatibility issues in most acrylic formulas will cause crater defects in a polyester powder coating due to the significant difference in surface tension between acrylic polymers and polyester resins. Because of this, you must keep acrylic based powders away from contact with other non-acrylic varieties. This can easily be accomplished by being very thorough with cleaning up when switching from an acrylic to other powders, and by having a dedicated application system.

As far as the cost, there is a reason lower-end vehicle manufacturers do not use acrylic powders (unlike BMW). Acrylic systems normally require a premium price compared to the cheaper polyester-based powder coatings. However, there really is a huge enhancement in performance levels between the two, which can often persuade manufacturers to pay the additional cost.

Markets and Applications for Acrylics

Acrylics are essentially the only powder chemistry that can truly meet the demanding specifications of any exterior automotive application including clear topcoats, trim parts and alloy wheels. In addition, any high-end farm implement application would be a desired for acrylic powder technology.